Automatic Self Cleaning Filters

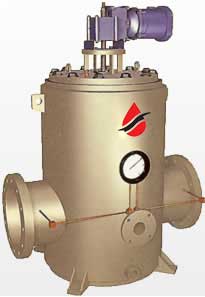

Automatic Self Cleaning / Backwash Filters

Any, functioning, filter gets fouled in the normal operation cycle and the fluid flow needs to be diverted or stopped for maintenance to be carried out. However, continuous operation cycles call, for filtration to be a continuous process with no interruption of flow for cleaning the filter.

For such applications AOF Filters offers automatic filters/strainers that dramatically cut down maintenance and downtime costs. These automatic filters /strainers have cylindrical elements equipped with backwash arm or wiper blade to dislodge surface deposits during the cleaning cycle.

Self Cleaning Wedge Wire / Slot Tube Type Filter

In this type of filter the flow is from the outside to the inside of the element eliminating the entry of debris on the clean side of the liquid flow. Manual online cleaning, semi automatic or fully automatic in operation.

The element is cleaned by rotating the element, manually or with an electric motor. The rotating element rubs against one or two stationary blades that remain in contact with the element.

Debris scraped / wiped off the surface is accumulated bottom of the filter where from it is flushed out through drain valve operated manually or automatically.

Single Element

| Pipeline Size | 50mm NB to 1000mm NB |

| Element | Cylindrical or Pleated type depending upon filtration area & requirement |

| Degree of Filtration | 50 Microns & above. Below 50 Microns special designs are available |

| End Connections | Designs are available with inline or offset end connections |

Multi Element

| Pipeline Size | Normally up to 400mm NB bigger size can be tailor – made to suit your requirement |

| Element | Tubular, Wedge wire wound (Slot tube or wire mesh type) |

| Degree of Filtration | 10 Microns & above. |